——NSR Intermodal’s Cross-Border Triumph in the Modernization Project of Siberian Cement Plant

On April 21,2025, an urgent call from SINOMA Zhongcai Eco-Materials Co., Ltd. Reached Yanni, NSR Intermodal’s Cross-border trucking director. 115 pieces of different sized equipment—weighing over 500 metric tons—had to be shipped from China before May 1. These were no ordinary cargo. From 19-meter-long steel beams to pressure-sensitive control cabinets, each piece was a lifeline for reviving a cement plant in Siberia. Delay meant thousands of workers would face another frozen construction season.

When Theory Met Reality

Initial load plans collapsed within hours. Factory loaders waved away schematics: “This 3–wide plate’s curvature is 5 cm larger than we expected”,“Those pipes can’t lie flat—their reinforcement rings will snap!” Four plans were rejected.

It seems that field truth always outweighs spreadsheet truth.

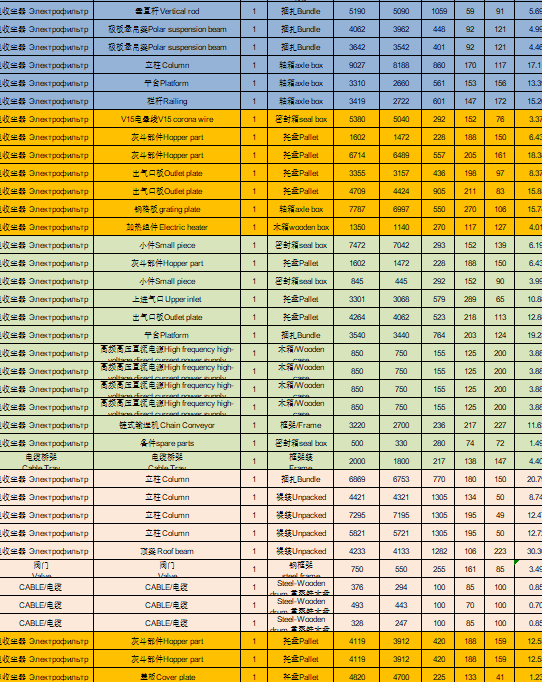

Nothing is more urgent than the customer’s expectation. NSR immediately dispatched Tony, an experienced operator to Pingdingshan. Armed with measuring equipment and humility, he arrived at the factory in the early morning on April 26. The moment he entered the warehouse , he was was totally astonished by the numerous sizes and shapes of cargo on the spot. In the following days, he spent all the time remeasuring dimensions with veteran workers. By dawn, carefully organized charts shared on the computer screen: “27 loaded, 88 to go.”

The Art of Industrial Tetris

The real challenge lay in the cargo’s wild diversity:

– Massive steel giants: 13-meter columns (Item 48/100), naked and gleaming, demanded custom bracing.

– Fragile hearts: Delicate heating control cabinets (Item 98/100) required climate-controlled isolation.

– Misfits in crates:: Corrugated plates (Item 61/100) huddled in crates resembling overgrown wood cases.

“It’s real-life Tetris with a 500-ton penalty for errors,” Tony joked grimly as they carefully organizing the loading of Truck 5. A 5.7-ton steel grating in an axle box needed millimeter-perfect spacing from adjacent heaters. Meanwhile, drum-packed cables (Item 9/9) nested like porcelain eggs between structural beams.

Redefining “Just-in-Time”

Late night on April 30th, the final truck roared to life under spring stars. What followed was a symphony of coordination: 115 tailor-made loading plans executed over four days, 17 trucks embarking on a relay race across borders—all converging flawlessly at Manzhouli Port by deadline.

At 3:00 PM on May 3rd, the Manzhouli port glowed with the taillights of a winding queue of trucks. NSR’s cross-border team moved with urgency—processing customs clearance, verifying documents, coordinating with Russian hauliers—knowing a single misstep could unravel days of planning. Yet their meticulously engineered loading plans became their superpower. When inspectors scrutinized Truck 7’s cargo, they found every strapping position and dunnage angle mirroring the factory’s original configuration—a carbon copy of Tony’s snapshots for these four days. The anticipated 72-hour clearance? Crushed to 48 hours. One by one, the oversized rigs rolled through the border gates, their steel cargo destined to reshape Siberia’s factory.

Beyond Promises, Beyond Borders

During the project debrief, SINOMA’s manager tapped a timestamped loading photo: “These snapshots speak louder than any promise.” Meanwhile, a text from their Russian partner lit up Tony’s phone: “This project gave our team invaluable experience.”

` At NSR, the acronym carries its weight—Never Stop Responding to your changing needs. Here, “mission impossible” gets dissected into hundreds of “mission accomplished” milestones by teams who understand: global logistics isn’t about moving freight—it’s about moving trust.